EX500

Residential Exhaust Duct Airtightness Tester

Leakage Detection in Residential Exhaust Systems

EX500 is a portable instrument designed for on-site airtightness testing of residential exhaust ducts. It integrates a high-capacity DC brushless fan delivering up to 1100 m³/h airflow at 500 Pa. With four-channel high-precision digital differential pressure sensors, Its adjustable PID pressure stabilization algorithm ensures reliable and accurate measurements, making it ideal for residential inspection, ventilation assessment, and compliance testing.

Product Highlights

Professional-grade air-tightness testing, versatile measurement, and intelligent control

Multi-Method Flow & Leak Detection

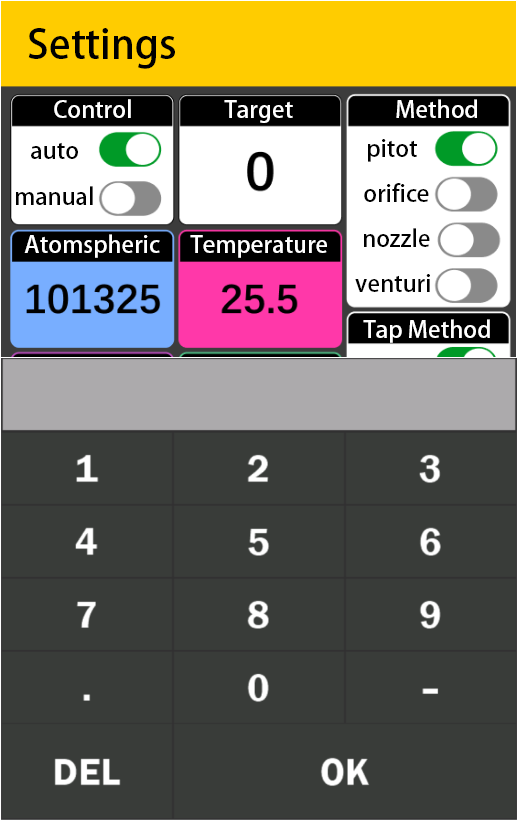

Pitot Tube, Nozzle, Orifice Plate, and Venturi

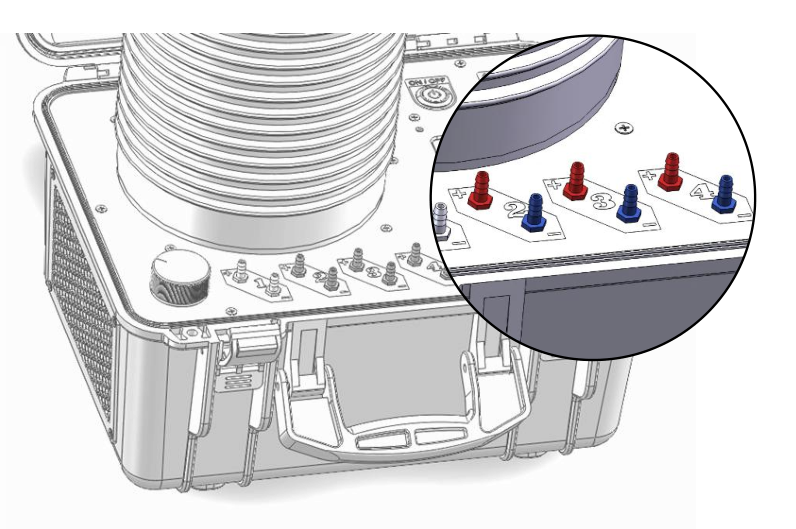

EX500 integrates four differential pressure measurement methods, enabling accurate airflow and leakage assessment for residential exhaust ducts. With four-channel high-precision sensors, it supports static pressure, Pitot velocity, nozzle, orifice, and Venturi testing. This versatility ensures compliance with multiple standards and adapts to complex on-site conditions

Intelligent PID Pressure Control

Stable test pressure, adaptive algorithm

Equipped with a digital brushless fan (max 1100 m³/h, 500 Pa), EX500 adopts an adjustable PID control algorithm to achieve rapid and stable pressure regulation. Automatic stabilization minimizes fluctuations, ensuring reliable leakage detection and consistent measurement accuracy in varying environments.

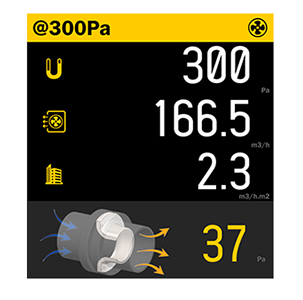

Real-Time Monitoring & Visualization

7-inch IPS capacitive touchscreen, dynamic curves

The 7-inch 1024×600 IPS display presents airflow, pressure, and leakage results in real time, complemented by trend curves for pressure and airflow stability. Interactive menus, intuitive parameter setup, and on-screen PID tuning make complex field operations simple and efficient

Flexible Configuration for Diverse Ducts

Customizable duct size, coefficient, and device setup

Users can freely input duct geometry, set Pitot coefficients, define nozzle/orifice diameters, and configure differential pressure tapping methods. EX500 automatically calculates unit leakage per surface area, adapting to different duct standards, construction projects, and acceptance tests

Portable, Robust, and Field-Ready

Compact structure, lightweight build, AC-powered

At only 9 kg with a durable housing, EX500 is designed for portability in residential and industrial environments. Powered by AC 220 V with ≤100 W consumption, it is engineered for long-duration field use. The robust design and reset/recovery functions ensure dependable operation in demanding test conditions

Comprehensive Application Coverage

From residential exhaust ducts to industrial ventilation

EX500 is purpose-built for airtightness and leakage measurement in residential exhaust systems, while also supporting industrial ventilation performance, duct commissioning, and energy efficiency evaluation. Its multi-sensor platform and intelligent control make it an all-in-one solution for professionals in HVAC, construction, and safety testing

Technical Specifications

| Processor | ARM Cortex-M, 240 MHz |

| Display | 7-inch IPS capacitive touchscreen, 1024×600 px |

| Touch | Capacitive |

| Static pressure range | 0–500 Pa |

| Static pressure accuracy | ±1.0% F.S. |

| Differential pressure range (Ch.2) | 0–500 Pa (supports Pitot tube / Orifice / Nozzle / Venturi) |

| Differential pressure accuracy (Ch.2) | ±1.0% F.S. |

| Velocity range (Ch.2) | 0–30 m/s |

| Pitot tube range (Ch.3) | 0–500 Pa, velocity 0–30 m/s |

| Pitot tube accuracy (Ch.3) | ±1.0% F.S. |

| Pitot tube range (Ch.4) | 0–500 Pa, velocity 0–30 m/s |

| Pitot tube accuracy (Ch.4) | ±1.0% F.S. |

| Max airflow | 1100 m³/h |

| Max pressure | 500 Pa |

| Rated voltage | AC 220 V |

| Rated power | ≤100 W |

| Weight | 9 kg |

| Dimensions | 480 × 330 × 220 mm |